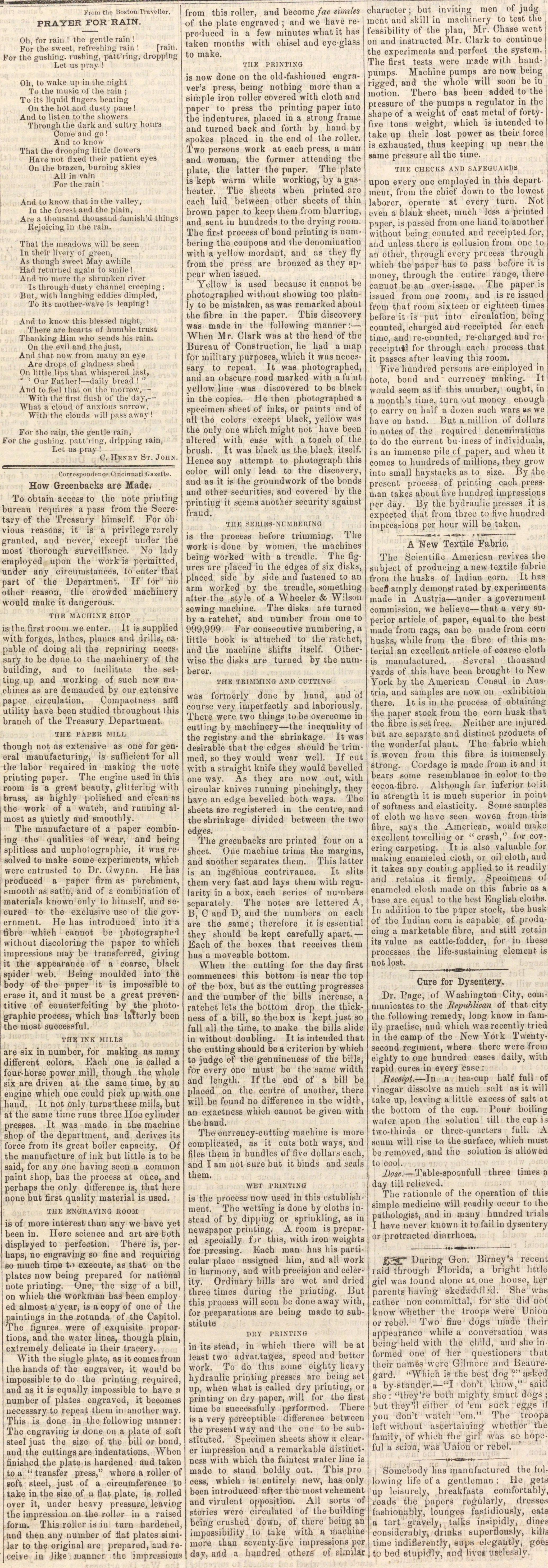

How Greenbacks Are Made

To obtain acocss to tho note printing bureau requives a pass from the Secretary of the Treasury himsclf. For obvious reasons, it is a privilege rnrely granted, aud never, except under the most thorough surveillance. No lady employed upon the work is permitted, under any eircumstanees, to enter that part of the Department. If for no other reasoa, the crowded inachiuery would make it dangerous. THE MACHINE SHOP is the first room we enter. It is supplied with forges, lathes, planes and Irills, capable of doing all the repairing necessary to be done to the machinery of the building, and to facilítate the setting up and working of such new machines as are demanded by our extensive paper cireulation. Coiapactness and utility have been studied throughout this branch of the Treasury Department. TUE PAPER JIILL though not as extensive as one for general mauufacturing, is sufficient for all the labor required in making the note priuting paper. The engine used in this room is a great beauty, glitteriug with brass, as highly polished and clean as the work of a watch, and running almost as t[üietly aud smoothly. The manufacture of a paper combinng tho qualities of wear, and being splitless and uuphoiographic, it was resolved to make some experimenta, which were eutrusted to Dr. Gwynn. He has produced a paper fiim as parchment, Kinooth as satin, and of L combination of inaterials known only to himself, and secured to the exclusive use of the government. He has introduced iuto it a Sbre which cannot be photographed without discoloriug the paper to which impressious be transferred, giving it the appearance of a coarse, black spider web. Beiug moulded into the body of the paper it is impossible to erase it, and it must be a great preventitive of couuterfeiting by the photographic process, which has láttorly been the most successful. THE INK MILLS are six in Duinber, for making as many different colors. Each one is called a four-borse power mili, though the whole six are driven at the same time, by an engine wbioh one could pick up with oue band. It not ouly turustbese milis, but at tbo same time runs tbree Hou cylinder presees. It was made in the machine shop of the departmeut, and derives its force from its great boiler capaoity. Of the manufacture of iuk but little is to be said, for auy one having seeu a common paint shop. has tho process at once, and perbaps the only difference is, that hore none but first quality material is used. TUE EN'GliAVING ItOO.M is of more interest than any we have yet been in. Here science and art are both displsyed to perfection. ïhere is, perhaps, no engraving so fine and requiring so much time t execute, as that on the plates now beiug prepared for natioual note priuting. One, the size of a bil!, on which the workman bas been employ ed almost a year, is a copy of one of the paintings in the rotunda of the Capítol. The figures were of exquisito proportions, and the water lines, though plaiu, extremely delicate in their tracery. AVith the siugle píate, as it comes from tho hands of the engraver, it would bo impossible to do the printing requiied, and as it is equally impossible to have a number of plates engravod, it becomes uecessary to repeat them iu auother way. ïhis is done iu the following manner: The engraviug is done on a píate of soft steel just the sizo of tlie bill or bond, and the cuttings are indentations. Whon ünished the plate is hardencd and takeu to a " transfer press," where a roller ol soft steel, just of a circumference to take in the size of a flat plate, is rolled over it, under heavy pressure, leaviog the impressiou on the rollor in a raised forui. This roller is iu turn haidened, and theu auy number of flat plates similar to the original are preparod, aud receive ia like ruauner the impretsious From tbis roller, and become fac simtks of the plate engraved ; and we have reproduccd in a few minutes what it ha taken months with chisel aud eyeglass to make. TUK PltlNTIXG is now done on the old-faahionod engraver's press, being nothing more tlian a simple iron roller eovered with eloth and paper to press the printing paper into the indentures, placed in a strotig frame aud turned back aud forth by hand by spokes placed in the end oí the roller. Two persons work at each press, u mau and woman, the former attending the plate, the latter the paper. Thü plate is kept warm vvhile workiug, by a gasheater. The sheets when printed are each laid between other sheets of thin brown paper to keep them from blun ing, and sent iu huudreds to the drying room. The lirt process of bond printing is uambering the coupons and the denomiuatiou with a yellow mordant, and as they rly from tlie press are bronzed as they appear when issued. Yellow is used because it cannot be photoüjraphcd without showing too plainly to be mistaken, as was remarked about the flbre iu the paper. ïhig diseovery was made in the füllowing manner: - When Mr. Clark was at the head of the Bureau of Oonstruetion, he had a map for military purposes, which it wus necessary to repeat. It was photographed, aud an obscure load marked with a fa ut vellow line was discovcred to be black in the copies. He then photographed a specimen sheet of iuks, or puints and of all the colors except black, yellow was the ouly one wliich might not have been altered with easo with a touch of the brush. It was black as the black itself. Henee any attempt to photograph this color will only lead to the diseovery, aud as it is the grouudwork of the bonds and other seeurities, and eovered by the printiug it seema another security agaiust fraud. TUE SER1ES-NUMBEUINO is the proeess beforo trimmiug. Tlie work is doue by women, the uiachines being vvorked with a troadle. The figures re placed ia the edges of six disks, placed side by side and fastened to an arm worked by the treadle, something alter the style of a Wheeler & Wilsou sewing machine. The disks are turncd by a ratehet and uumber froui ono to 099,999. For consecutive numbering, a liltle hook is attached to the ratchet, and the machine shifts itself. Olhervvise the disks are turued by the duidberer. THE TRIMMIN'G AN CÜTTINO was fonnerly done by hand, aud of course very imperfectly and laboriously. Thcre were two things to be overeóme in cutting by machinery - the inequality of the registry and the sbrinkagc. It was desirablo that the edges sbould bc trimmed, so tbey would wear well. If out with a straight knife they would bevelled one way. As they aro now cut, with circular knives running pinchingly, they have an edge bevelled boih ways. The sheets are registered in the centre, and the shrinkage divided between the two edges. The greenbacks are printed fciur on a sheet. One machino trinis the margins, and another soparates them. This lattor is au ingenious coutrivauce. It ülits them very fast and lays them with rcgularity in a box, each series of uu'iibers separately. The notes are lettered A, B, C aud D, and the numbers on each are the same; thorefore it is es=eutial they sbould be kept carefully apart. - Each of the boxes that receives them has a moveable bottoin. When the cutting for the day first commences this bottom is near the top of the box, but as the cutting progresses and the uumber of the bilis increase, a ratehet Iets the bottom drop the thickness of a bilí, so the box is kept just so full all tho time, to inake the bilis slide in without doubling. It is iuteuded that the eutting should be a criterion by whieh to judge of the genuineucss of the bilis, for every one must be the same width and length. If the end of a bilí be placed oü the centre of anotber, there will be found no ditïerence in the widtt, an exactness which cauuot be giveu with the hand. The curreucy-cuttiug machine is more complicated, as it cuts both ways, and files them in bundlcs of five dollai b each, and I am not sure but it binds and seáis them. WET 1'ltlNTlNO is the process now used in this establishment. The wetting is done by cloths instead of by dippiug or spriukling, as iu newspaper priuting. A room is prepared speoially f jr this, with iron weights for pressing. Each man has his particular placo assigned him, and all work in harmouy, and with precisión and celerity. Ordinary bilis are wet and dried three times duriug the priuting. But this procesa will soou be doue away with, for preparatious are being made to substitute DRY PRÍSTINO in its stead, in which thero will be at least two advar.tages, speed and botter work. To do this soine eighty heavy hydraulic priutiug presses aro beiug set up, when what is callcd dry priutiug, or printiog ou dry paper, will for the first time be successfully pprformed. There is a very perceptible dift'erenue betweeu the present way and tho one to be subHtituted. Specimen sheets show a clearer impression and a remarkablo distiuetness with which the fuiutest water line is mado to stand boldly out. This pro cess, whieh is entircly new, has only been introduced after the most vehement and viruleut opposition. All sorts of stories wero circulated of the building being crushed dowu, of there being an impossibility to take with a machine more thau seventy-íive impressions per dav. aild a huudred others of similar character ; but inviting men of judg ment and skill in machinery to test tlio feasibility of the plan, Mr. Chase went OD and instructed Mr. Clark to continue the experimenta and perfect the system. The fitst tests werc ir.ade with i pumps. Machine pumpa are now being rigged, and the whole will soon bo iu motion. Thcie bas been added to the piessure of the pumps a regulator in the sluipe of a weight of cast metal of fortyfive tons weight, which is iutended to take up their lost power as their lorce is exhausted, thus keeping up near the same pressure all the time. TUK CHECKS AND SAKKQLAKDS upon every oue employed in this ( ment, from the chief down to the lowe&t laborer, opérate al every turn. Not even a blauk sheet, uiuch less a printed piper, is passed from oue hand to another without baing couuted aiid receipted for, aud unless thero is collusion from ene to an other, through every precess through which the paper has to pass bcfore it ia money, through the entire range, ihere cacuot be au over-issue. The paper is issued from oue room, aud is re issued from that room sixteen or eighteen times before it is put into circulation, being couuted, charged aud receipted for eatèfi time, and re-counted, re-charged and rereceiptcjd for through each process that it passes after leaviug this room. Five hundred persons are employed in note, bond aud curreney makiog. It would seem as if this uuuiber, ought, iu a mouth's time, turn out money cnough to earry on half a dozen sueh wars as we have on hand. But a milliou of dollars iu uotes of the roquired deuomiuations to do the current buincss of individuals, is an immense pile cf paper, aud when it comes to huudreds of millions, they grow into small haystacks as to size. Ï5y the present process of printing each pressnian takes aboutfive hundred impressious per day. By the hydraulic presses it is expected that from threo to tive huudrud impresnions per hour will be taken.

Article

Subjects

Old News

Michigan Argus