Cost Of Production

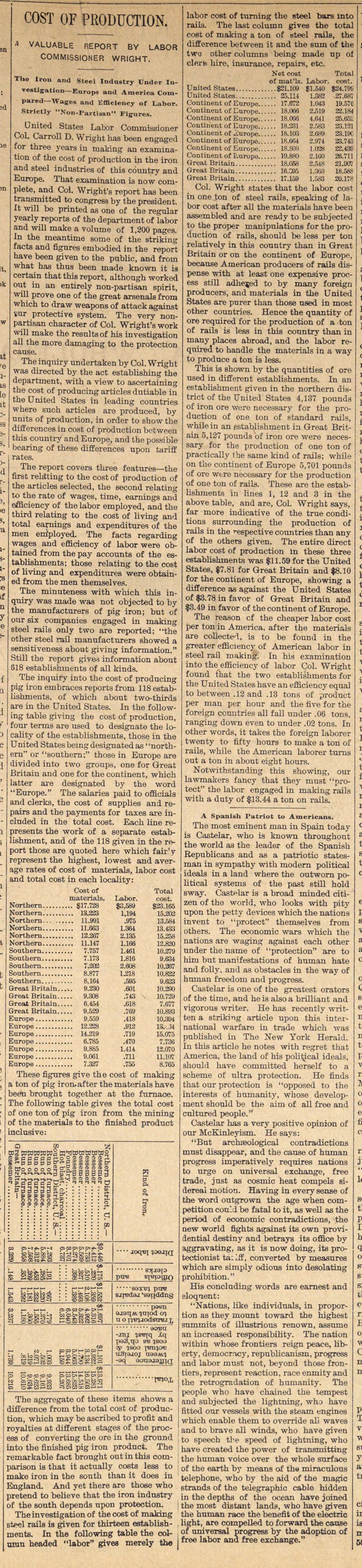

ünited States Labor Commissioner Col. Carroll D. Wright has been engaged for three years in niaking an examination of the cost of production in the iron and steel industries of this country and Europe. That examination is now complete, and Col. Wright's report has been transmitted to congress by the president. It will be printed as one of the regular yearly reports of the department of labor and will rnake a volume of 1,200 pages. In the meantime some of the striking facts and figures embodied in the report have been given to the public, and froin what has thus been made known it is certain that this report, although worked out in an entirely non-partisan spirit, will prove one of the great arsenals from which to draw weapons of attack against sur protective system. The very nonpartisan character of Col. Wright's work will make the resultsof Ms investigation all the more damaging to the protection cause. The inquiry undertaken by Col. Wright was directed by the act establishing the departinent, with a view to ascertaining the cost of prodncing articles dutiable in the United States in leading conntries where such artioles are produeed, by units of production, in order to show the differences in cost of production between this country and Europe, and the possible hearing of these differences upon tariff rates. The report covers three features - the first reldting to the cost of production of the articles selected, the second relating to the rate of wages, time, earnings and efficiency of the labor employed, and the third relating to the cost of living and total earnings and expenditures of the men eniployed. The facts regarding wages and efficiency of labor were obtained from the pay accounts of the establishments; those relating to the cost of living and eipenditures were obtained from the men themselves. The minuteness with which this inquiry was made was not objected to by the manufacturers of pig iron; but of our six companies engaged in making steel rails only two are reported; "the other steel rail manufacturers showed a sensitiveness about giving information." Still the report give.5 information about 618 establishments of all kinds. The inquiry into the cost of producing pig iron embraces reports f rom 118 establishments, of which about two-thirds are in the United States. In the following table giving the cost of production, four terms are used to designate the locality of the establishments, those in the United States bemg designated as "northern" or "southern;" those in Europe are divided into two groups, one for Great Britain and one for the continent, which latter are designated by the word "Europe." The salaries paid to officials and clerks, the cost of supplies and repairs and the payments for taxes are included in the total cost. Each line represents the work of a separate establishment, and of the 118 given in the report those are quoted here which fair' y represent the highest, lowest and average rates of cost of materials, labor cost and total cost in each locality: These figures give the cost of maMng a ton of pig iron.after the materials have been brought together at the furnace. The following table gives the total cost of one ton of pig iron from the mining of the materials to the finished product inclusive: The aggregate of these items shows a difference from the total cost of production, which may be ascribed to profit and royalties at different stages of the process of converting the ore in the ground into the finished pig i ron product. The remarkable f act brought out in this comparison is that it actually costa less to make iron in the south than it does in England. And yet there are those who pretend to believe that the iron indnstry of the south depends upon protection. Theinvestigation of the cost of making steel rails is given f or thirteen establishment. In the following table the column headed "labor" gives merely the labor cost of turning the steel bars into rails. The last column givea the total cost of making a ton of steel rails, the difference between it and the sum of the two other colurnns being made np of clerh hire, insurance, repairs, etc. Col. Wright states that the labor cost in one ton of steel rails, speaking of labor cost after all the materials have been assembled and are ready to be subjected to the proper nianipulations for the production of rails, should be less per ton relatively in this country than in Great Britain or on the continent of Europe, because American producers of rails dispense with at least one expensive process still adlieed to by many foreign producers, and materials in the United States are pnrer than those used in most other countries. Henee the quantity of ore required for the production of a ton of rails is less in this country than in many places abroad, and the labor required to handle the materials in a way to produce a ton is less. This is shown by the quantities of ore nsed in different establishments. In an establishment given in the northern district of the United States 4,137 pounds of iron ore were necessary for the production of one ton of standard rails, while in an establishment in Great Britain 5,127 pounds of iron ore were necessary for the production of one ton of practically the same kind of rails; while ! on the continent of Europe 5,701 pounds of ore wtre necessary for the production of one ton of rails. These are the establishments in lines 1, 12 and 3 in the above table, and are, Col. Wright says, far more indicative of the true conditions surrounding the production of rails in the i-espective countries than any of the others given. The entire direct labor cost of production in these three establishments was $11.59 for the United States, $7.81 for öreat Britain and $8.10 for the continent of Europe, showing a difference as against the United Statea of $3.78 in favor of Great Britain and $3.49 in favor of the continent of Europe. The reason cf the cheaper labor cost per ton in America, after the materials are collected, is to be found in the greater efficiency of American labor in steel rail making. In his examination into the efficiency of labor Col. Wright found fhat the two establishments for the United States have an efficiency equal tobetween .12 and .13 tons of product per man per hour and the five for the foreign countries all f all under .06 tons, ranging down even to under .02 tons. In other words, it takes the foreign laborer twenty to fif ty honrs to make a ton of rails, while the American laborer turns out a ton in about eight hours. Notwithstanding this showing, our lawmakers fancy that they must "protect" the labor engaged in making rails with a dnty of $13.44 a ton on rails.

Article

Subjects

House Education and Labor Committee

Old News

Ann Arbor Argus

Carroll D. Wright