Armen Cleaners - Wool Spotting Department, March 1949 Photographer: Maiteland Robert La Motte

Year:

1949

Published In:

Ann Arbor News, April 18, 1949

Caption:

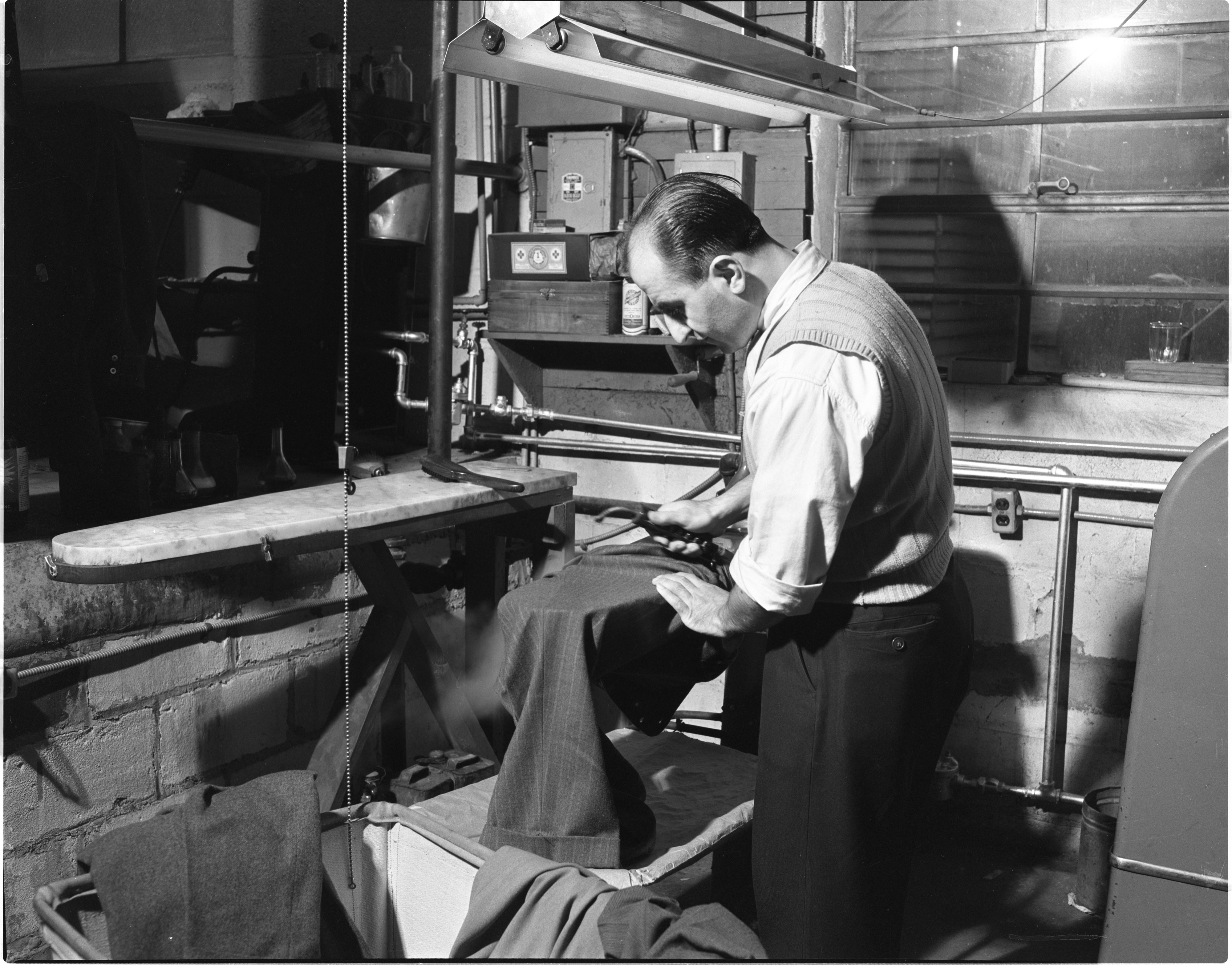

WOOL SPOTTING DEPARTMENT 1. In the above illustration...an experienced spotter is going over a pair of pants which have previously been dry cleaned. Every square inch of the garment is checked, under a powerful light, for spots. Every effort is made to remove spots, by using all of the chemicals that modern science provides. 2. The marble top spotting board in the background is used to re-treat certain spots with chemicals, oils, etc. After such a spotting treatment each garment is put through another full cycle of recleaning.

Ann Arbor News, April 18, 1949

Caption:

WOOL SPOTTING DEPARTMENT 1. In the above illustration...an experienced spotter is going over a pair of pants which have previously been dry cleaned. Every square inch of the garment is checked, under a powerful light, for spots. Every effort is made to remove spots, by using all of the chemicals that modern science provides. 2. The marble top spotting board in the background is used to re-treat certain spots with chemicals, oils, etc. After such a spotting treatment each garment is put through another full cycle of recleaning.

Copyright

Copyright Protected

- Read more about Armen Cleaners - Wool Spotting Department, March 1949

- Log in or register to post comments

Armen Cleaners - Silk Spotting Department, March 1949 Photographer: Maiteland Robert La Motte

Year:

1949

Published In:

Ann Arbor News, April 18, 1949

Caption:

SILK SPOTTING DEPARTMENT 1. In this illustration the operator, a highly trained expert, is working on a silk dress. He, also, has on hand all the chemical weapons that modern science can provide. 2. Tumbler...especially designed for spotters use. It is used to dry steam-moistened areas of various garments by means of gentle tumbling in an adjusted, temperature-controlled chamber. 3. This equipment with dual opening is also used to quickly and properly dry the spotted areas of the garments. Temperature-controlled air is forced up from underneath by means of fans. Note that the garments hang in the shape they would in their normal position.

Ann Arbor News, April 18, 1949

Caption:

SILK SPOTTING DEPARTMENT 1. In this illustration the operator, a highly trained expert, is working on a silk dress. He, also, has on hand all the chemical weapons that modern science can provide. 2. Tumbler...especially designed for spotters use. It is used to dry steam-moistened areas of various garments by means of gentle tumbling in an adjusted, temperature-controlled chamber. 3. This equipment with dual opening is also used to quickly and properly dry the spotted areas of the garments. Temperature-controlled air is forced up from underneath by means of fans. Note that the garments hang in the shape they would in their normal position.

Copyright

Copyright Protected

- Read more about Armen Cleaners - Silk Spotting Department, March 1949

- Log in or register to post comments

An Illustrative Tour Of A Dry Cleaning Plant, No. 5 - Armen Cleaners

Parent Issue

Day

18

Month

April

Year

1949

Copyright

Copyright Protected

Armen Cleaners - Flexform, April 1949

Year:

1949

Published In:

Ann Arbor News, April 25, 1949

Caption:

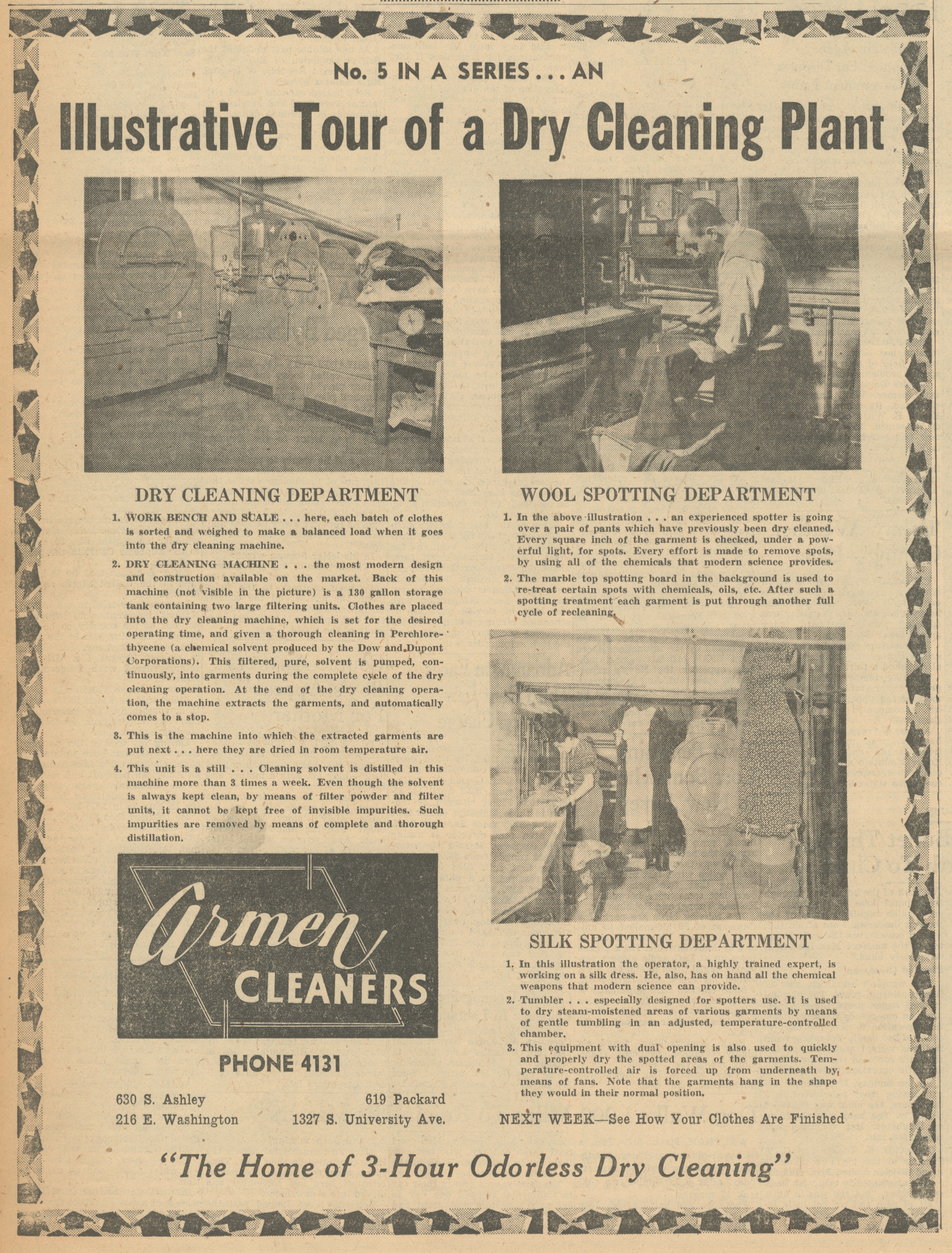

1. This is a FLEXFORM...an up-to-the-minute, modern machine used for re-shaping dresses and formals to their original size and shape. Dials, on the face of the equipment illustrated, are set to the exact measurements taken of the garment before cleaning, then, the garment is put on the FLEXFORM and every part of the dress is brought back to its original size and shape by means of moisture controlled steam and hot air forced up through the garment from the base of the machine. 2. MEASURING CHART - Used to measure garments before cleaning process if they are to be shaped by FLEXFORM after cleaning. 3. DRESS FASHIONER - This machine - a very modern piece of equipment - is used only to finish certain special garments. It operates in the same manner as the FLEXFORM but, does not have the sizing effect. 4. TROUSER-FORMR - This machine plays a highly important part in the reshaping and forming of certain dry cleaned trousers. Without the use of this FORMR most pants would not look right nor fit the body properly.

Ann Arbor News, April 25, 1949

Caption:

1. This is a FLEXFORM...an up-to-the-minute, modern machine used for re-shaping dresses and formals to their original size and shape. Dials, on the face of the equipment illustrated, are set to the exact measurements taken of the garment before cleaning, then, the garment is put on the FLEXFORM and every part of the dress is brought back to its original size and shape by means of moisture controlled steam and hot air forced up through the garment from the base of the machine. 2. MEASURING CHART - Used to measure garments before cleaning process if they are to be shaped by FLEXFORM after cleaning. 3. DRESS FASHIONER - This machine - a very modern piece of equipment - is used only to finish certain special garments. It operates in the same manner as the FLEXFORM but, does not have the sizing effect. 4. TROUSER-FORMR - This machine plays a highly important part in the reshaping and forming of certain dry cleaned trousers. Without the use of this FORMR most pants would not look right nor fit the body properly.

Copyright

Copyright Protected

- Read more about Armen Cleaners - Flexform, April 1949

- Log in or register to post comments

Armen Cleaners - Silk Finishing Department, March 1949 Photographer: Maiteland Robert La Motte

Year:

1949

Published In:

Ann Arbor News, April 25, 1949

Caption:

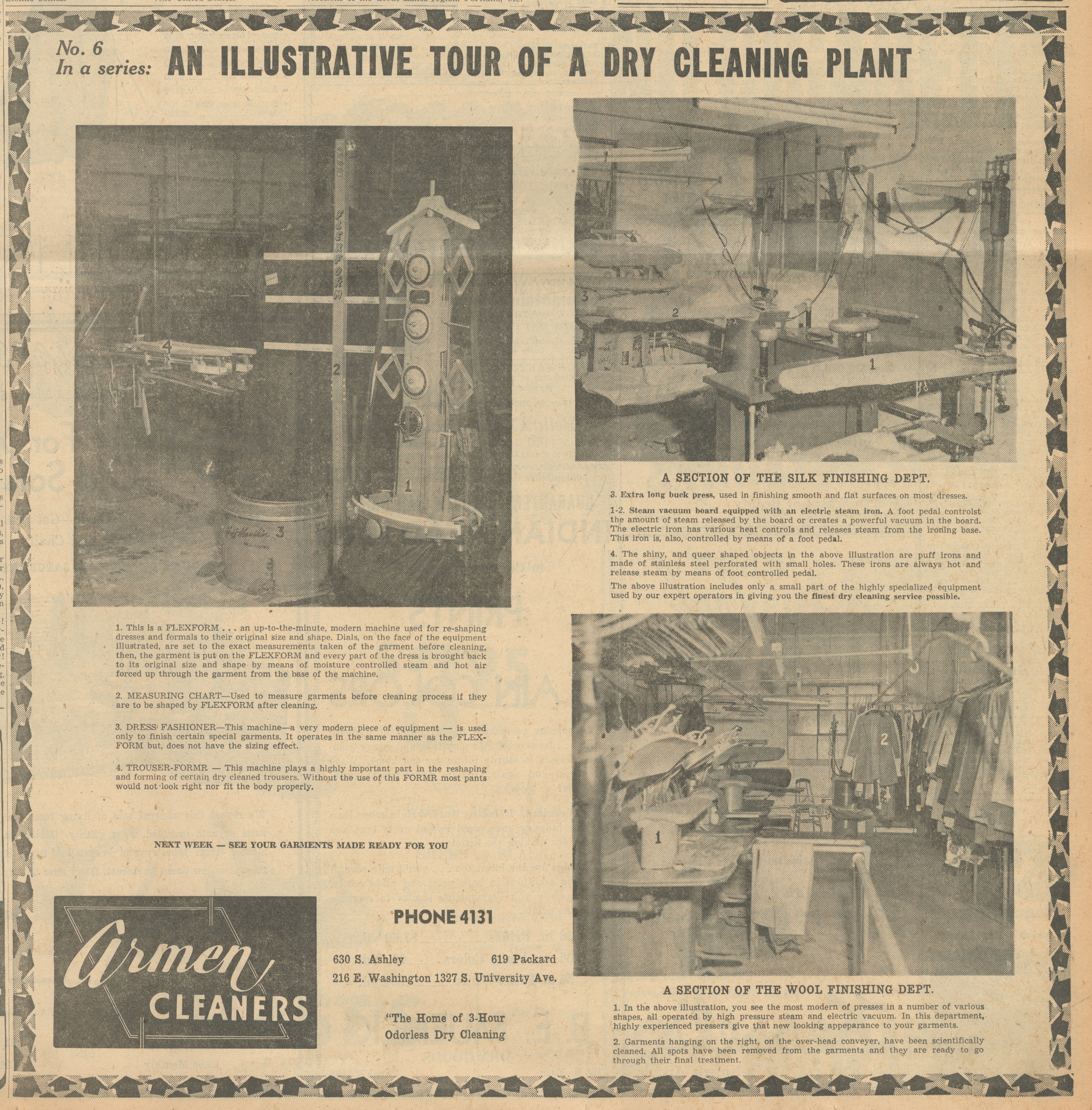

A SECTION OF THE SILK FINISHING DEPT. 3. Extra long buck press, used in finishing smooth and flat surfaces on most dresses. 1-2. Steam vacuum board equipped with an electric steam iron. A foot pedal controls the amount of steam released by the board or creates a powerful vacuum in the board. The electric iron has various heat controls and releases steam from the ironing base. This iron is, also, controlled by means of a foot pedal. 4. The shiny and queer shaped objects in the above illustration are puff irons and made of stainless steel perforated with small holes. These irons are always hot and release steam by means of foot controlled pedal. The above illustration includes only a small part of the highly specialized equipment used by our expert operators in giving you the finest dry cleaning service possible.

Ann Arbor News, April 25, 1949

Caption:

A SECTION OF THE SILK FINISHING DEPT. 3. Extra long buck press, used in finishing smooth and flat surfaces on most dresses. 1-2. Steam vacuum board equipped with an electric steam iron. A foot pedal controls the amount of steam released by the board or creates a powerful vacuum in the board. The electric iron has various heat controls and releases steam from the ironing base. This iron is, also, controlled by means of a foot pedal. 4. The shiny and queer shaped objects in the above illustration are puff irons and made of stainless steel perforated with small holes. These irons are always hot and release steam by means of foot controlled pedal. The above illustration includes only a small part of the highly specialized equipment used by our expert operators in giving you the finest dry cleaning service possible.

Copyright

Copyright Protected

- Read more about Armen Cleaners - Silk Finishing Department, March 1949

- Log in or register to post comments

Armen Cleaners - Wool Finishing Department, March 1949 Photographer: Maiteland Robert La Motte

Year:

1949

Published In:

Ann Arbor News, April 25, 1949

Caption:

A SECTION OF THE WOOL FINISHING DEPT. 1. In the above illustration, you see the most modern of presses in a number of various shapes, all operated by high pressure steam and electric vacuum. In this department, highly experienced pressers give that new looking appearance to your garments. 2. Garments hanging on the right, on the over-head conveyor, have been scientifically cleaned. All spots have been removed from the garments and they are ready to go through their final treatment.

Ann Arbor News, April 25, 1949

Caption:

A SECTION OF THE WOOL FINISHING DEPT. 1. In the above illustration, you see the most modern of presses in a number of various shapes, all operated by high pressure steam and electric vacuum. In this department, highly experienced pressers give that new looking appearance to your garments. 2. Garments hanging on the right, on the over-head conveyor, have been scientifically cleaned. All spots have been removed from the garments and they are ready to go through their final treatment.

Copyright

Copyright Protected

- Read more about Armen Cleaners - Wool Finishing Department, March 1949

- Log in or register to post comments

An Illustrative Tour Of A Dry Cleaning Plant, No. 6 - Armen Cleaners

Parent Issue

Day

25

Month

April

Year

1949

Copyright

Copyright Protected

Armen Cleaners - Tailoring Department, March 1949 Photographer: Maiteland Robert La Motte

Year:

1949

Published In:

Ann Arbor News, May 2, 1949

Caption:

THE ABOVE ILLUSTRATION SHOWS OUR TAILORING DEPARTMENT. In this department an experienced tailor on men's and especially ladies' clothing takes care of all alterations, repairs, making new pockets, sewing zippers, etc.

Ann Arbor News, May 2, 1949

Caption:

THE ABOVE ILLUSTRATION SHOWS OUR TAILORING DEPARTMENT. In this department an experienced tailor on men's and especially ladies' clothing takes care of all alterations, repairs, making new pockets, sewing zippers, etc.

Copyright

Copyright Protected

- Read more about Armen Cleaners - Tailoring Department, March 1949

- Log in or register to post comments

Armen Cleaners - Finished Garment Racks, March 1949 Photographer: Maiteland Robert La Motte

Year:

1949

Published In:

Ann Arbor News, May 2, 1949

Caption:

THIS ILLUSTRATION SHOWS THE FINISHED GARMENT RACKS. Here garments await your demand to be put into service. Thus ends our brief tour...you have now followed your garment through the complete dry cleaning and finishing process.

Ann Arbor News, May 2, 1949

Caption:

THIS ILLUSTRATION SHOWS THE FINISHED GARMENT RACKS. Here garments await your demand to be put into service. Thus ends our brief tour...you have now followed your garment through the complete dry cleaning and finishing process.

Copyright

Copyright Protected

- Read more about Armen Cleaners - Finished Garment Racks, March 1949

- Log in or register to post comments

Armen Cleaners - Final Inspection & Assembly Department, April 1949

Year:

1949

Published In:

Ann Arbor News, May 2, 1949

Caption:

THIS IS THE FINAL INSPECTION AND ASSEMBLY DEPARTMENT. Fully finished garments come to this department via an overhead conveyor. Each garment goes through a scrupulous inspection for correct finishing, missing buttons, small rips, etc. If for any reason the garment is found unsatisfactory it is sent to the proper department to be re-done. If the garment is found satisfactory in every respect, it is identified and placed on one of the circular assembly racks. All items belonging to the same order are automatically assembled on one section of these two racks.

Ann Arbor News, May 2, 1949

Caption:

THIS IS THE FINAL INSPECTION AND ASSEMBLY DEPARTMENT. Fully finished garments come to this department via an overhead conveyor. Each garment goes through a scrupulous inspection for correct finishing, missing buttons, small rips, etc. If for any reason the garment is found unsatisfactory it is sent to the proper department to be re-done. If the garment is found satisfactory in every respect, it is identified and placed on one of the circular assembly racks. All items belonging to the same order are automatically assembled on one section of these two racks.

Copyright

Copyright Protected