Gelman To Celebrate Best Year Ever

The Ann Arbor News, Sunday, November 17,1974

The Science Beat

Gelman To Celebrate Best Year Ever

BY LARRY BUSH

News Science Editor

From a Chelsea basement to a worldwide, multi-million-dollar business through scientific research aimed at advancing the quality of medical care and fighting pollution. That's the story of Ann Arbor's Gelman Instrument Co.

On Jan. 18, a “scientific open house” for area scientists, engineers, physicians and technicians will be held at the firm's local plant and laboratories at 600 S. Wagner Rd.

Postponed from December 1 the open house was scheduled to mark the 15th anniversary this year of the official founding of the firm, and its highest sales and earnings in its history.

In the 12 months preceding last July 31, Gelman Instrument Co. recorded sales of $10,830,900, compared to $7,413,100 for the previous fiscal year, and a far cry from the $52,000 the firm earned in 1958-59.

Actually, however, the story of this unusual, science-based firm goes back even farther to when Charles Gelman, its founder and president, became a principal chemist for an air pollution study in 1956 in Louisville, Ky.

It was in Louisville that Gelman, a graduate of Syracuse University, created an air sampling-device which was to lead to the formation of the firm. Moving to Chelsea the next year and enrolling in the U-M School of Public Health to work on a master’s degree, he started perfecting and building the devices in the basement of his home and got his first 11 orders.

After receiving his master’s degree from the U-M in June, 1958, other orders followed and Gelman expanded his one-man operation by hiring two people and renting a building on Chelsea's Main Street.

Gelman moved his operations from expanded facilities in Chelsea to a new 40,000-square-foot plant with a work force of 48 on the Wagner Road site in 1963. Today that plant has been expanded to 85,000 square feet, and the firm has 230 employes.

The firm also has plants in England and Italy which produce bio-medical products, has a partially-owned manufacturing subsidiary in Australia and a sales subsidiary in France, and has representatives in all of the world's major countries. Its products are sold world-wide.

But the heart and soul of this Ann Arbor industry is the science and engineering research and development which has kept it competitive and leads in great measure to its booming revitalization following a short period of uncertainty.

In view of this, I recently visited the Gelman Instrument Company’s Ann Arbor facilities to learn more about the research behind the products that are important in protecting the health of mankind.

Monty Vincent, Gelman vice president, met me in the plant’s lobby and escorted me on a tour of its laboratories and production units. He informed me that “about 65 per cent of the corporate business is international, and 35 per cent of what we produce in Ann Arbor goes to foreign countries.”

Later on, in the firm’s shipping department, I saw boxes with mailing labels for Switzerland, Thailand, Australia, Israel, the Philippines, Costa Rica, Portugal, Lebanon and France.

Membrane filters of many varieties and for a number of purposes, and the equipment and instruments which are used in connection with them, make up the largest part of Gelman Instrument's production and are the basis for its most extensive research.

“Some of the membrane production has now gone from two to three shifts" because of the recently increased demand, Vincent says.

These membranes are a key element in Gelman-developed methods for detecting air and water pollution, in providing ultra-clean air for certain industrial and laboratory work, in identifying drugs, in filtering molds out of wine, for removing bacteria and other uses.

“It all started with membranes, and then Gelman went into building the equipment to go along with it,” the firm’s vice president says.

Gelman electrophoresis equipment, in which special membranes are used, is used in hospitals and research laboratories for analysis of blood serum proteins, hemoglobins and lipoproteins.

The firm's engineers have developed instruments in which the change of power separates different components, and it can even be used to identify the tissue of different species of fish — so the U.S. Food and Drug Administration (FDA) can detect if some other kind of fish is being put in cans labeled tuna, for example.

"We are the world’s largest manufacturer of electrophoresis equipment on a dollar volume basis,” Vincent says.

Gelman’s chromatography system, based on instant thin layer chromatography in which a sample is qualitatively separated into its components, can be used for detection of drugs of abuse, such as heroin, and also to test for the maturity of a fetal lung to determine if a child can be saved, for example.

“Just this month we came out with a small disposable chamber to use with a kit containing all the necessary chemicals to make tests the instant a baby is delivered,” Vincent says.

Going through the plant out on Wagner Road, we paused at its Mechanical Engineering Laboratory in which Gelman engineers develop membrane systems and new materials, as the vice president says "to broaden the horizons of filtration.” Then there is the Electrical Engineering Laboratory where other engineers do research and development on the electrical equipment manufactured by Gelman to use in its filtration systems.

A Polymer Chemistry Laboratory is located right above the membrane production area in which membranes, that are basically plastic films saturated with polymers and resins and stirred up like pancake batter, are rolled out on a 100-foot-long stainless steel belt.

It is a tricky business requiring constant quality control and monitoring with delicate instruments along the way.

There is another machine to produce a membrane which coats both sides of a special kind of nylon and is known as supportive membrane. “We are leaders in the world in producing this membrane,” Vincent says.

A third machine is used for making a still different kind of membrane which is used mostly in scientific research. “The machine is in the process of being changed for making a unique membrane for desalting of sea water," the Gelman official says.

This is an important development which could aid in food production in the drier regions of this food-short world.

All along the line chemists, biochemists, biologists and engineers play a major role, not only in research and development, but as consultants as well. Machinists in the facility’s machine shop, draftsmen, and people working on equipment circuit boards, are all in touch with the scientists and engineers.

Behind it all is Gelman, a research chemist who started his professional career in the U.S. Army Chemical Corps and in 1967 received the Ann Arbor Jay-cees Distinguished Service Award.

He was cited in part for his creation, “from a singular idea for the need for efficient air pollution detection equipment . . .," an idea, which among others, he has brought to reality.

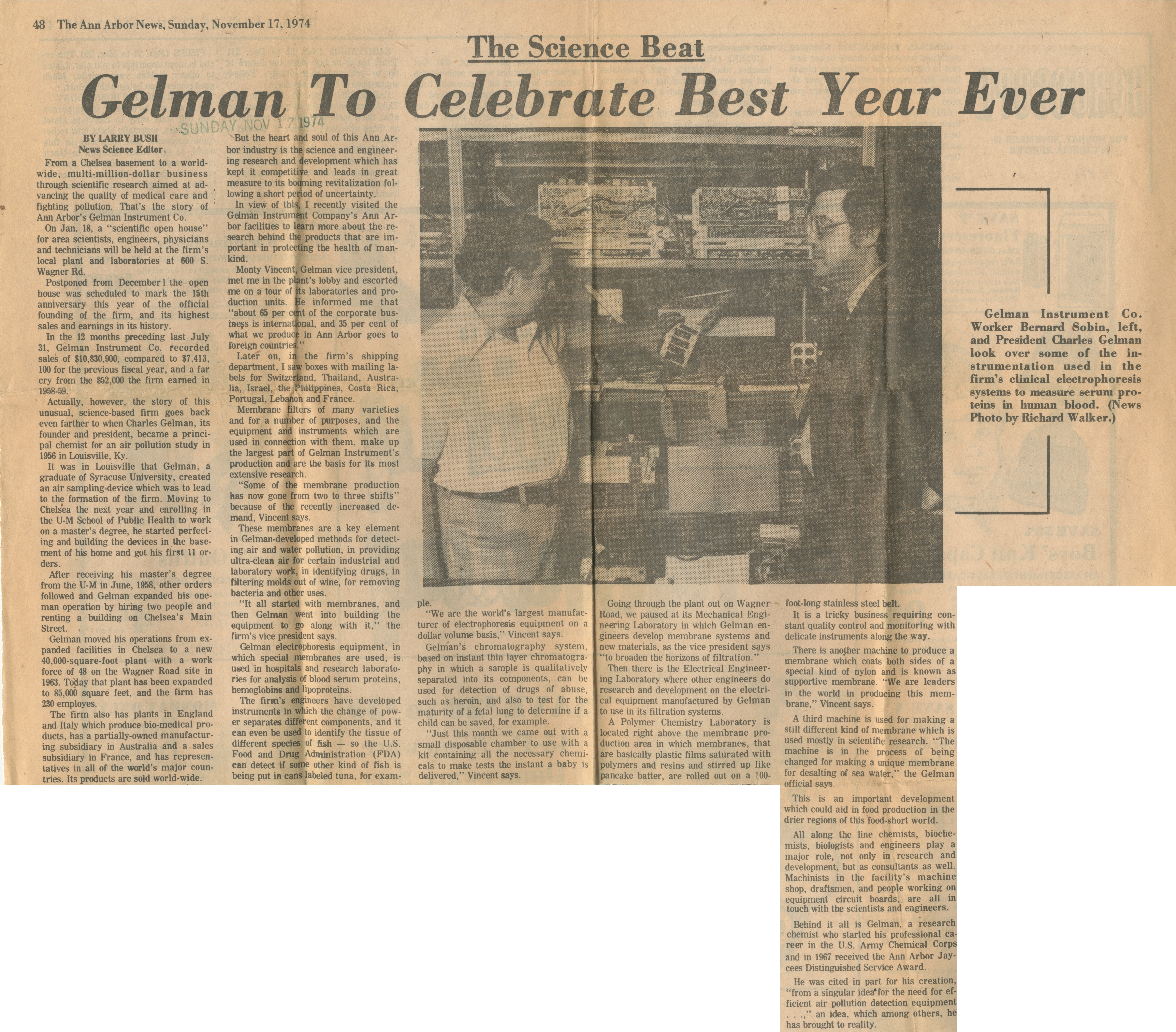

Gelman Instrument Co. Worker Bernard Sobin, left, and President Charles Gelman look over some of the instrumentation used in the firm’s clinical electrophoresis systems to measure serum proteins in human blood. (News Photo by Richard Walker.)

Article

Subjects

Larry Bush

University of Michigan - School of Public Health

Syracuse University - Alumnus

Pall Gelman Dioxane Groundwater Contamination Cleanup History

Gelman Sciences Inc.

Gelman Instrument Co.

Has Photo

Old News

Ann Arbor News

Monty Vincent

Charles Gelman

Richard Walker

600 S Wagner Rd